Pulleys are parts of disc hubs, and are generally relatively large in size. In the manufacturing process of pulleys, casting and forging are generally the main ones. Generally, larger sizes are designed with casting methods, and the materials are generally cast iron. The main reason is that cast iron has better casting performance. Cast steel is rarely used, mainly because the casting performance of steel is poor; generally smaller sizes can be designed as Forged, the material is steel. The pulleys for crushers are usually cast iron.

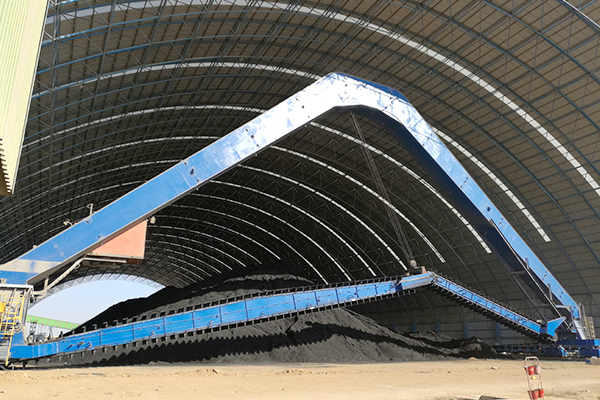

belt conveyor for bulk materials

Pulleys are mainly used for long-distance transmission of power, such as the power output of small diesel engines, automobiles, mining machinery, machining equipment, textile machinery, packaging machinery, power transmission of some small horsepower motorcycles, power transmission of agricultural machinery, etc. Belt pulley of combined crusher.

The following points should be paid attention to during the installation of the crusher pulley:

The first is that gasoline must be used in the last cleaning before assembly to ensure that all parts are clean and dry, to ensure that the mating surfaces are tightly matched and free of oil, and there is sufficient friction.

Secondly, the hexagon socket bolts used for assembly should also be washed with gasoline and dried before assembly. Do not coat the bolts or screw holes with lubricating oil or grease to ensure sufficient friction self-locking ability after the bolts are tightened.

The third point is that when the three hexagon socket bolts are about to be installed in place, they need to be tightened in turn to ensure that the cone sleeve receives uniform axial force and ensures that the pulley and the cone sleeve are coaxially positioned well.

The fourth point is to check and adjust the relative position of the main and driven pulleys after the pulley is tightened to ensure that the two pulleys are on the same plane and the belt tension is moderate.

The fifth point is to check and measure the length of the hexagon socket bolts for assembly before installation to ensure that the assembly bolts can withstand the bottom end of the blind hole of the cone sleeve after being tightened, to ensure that the cone surface fits tightly, and to ensure that the bolt receives the reverse thrust from the bottom end of the blind hole. , It produces the same anti-loosening effect as the double nut principle.

The sixth point is that the pulley cover should be intact and installed firmly to ensure that the belt will not break or the pulley will become loose during operation, which may cause a major safety accident. The taper sleeve is a vulnerable part. After a long time of operation, the inner hole and the chain groove may be damaged. It should be checked before each assembly. If the defect is found, the spare part should be replaced in time. Always ensure that all parts of the equipment are in ideal working conditions